|

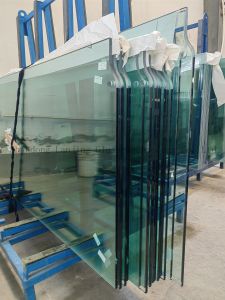

Heat soaked glassPRODUCTION CAPABILITY

Collect

overview

Some architectural projects require heat soaking as an extra safety precaution.

Heat Soaked Glass goes through an additional process to toughening. This can help to prevent spontaneous combustion that sometimes takes place with toughened glass due to nickel inclusions.

Heat Soaked Glass is heated up to 290°C before being bathed at the same temperature to neutralise the nickel and ensure optimum stability. The obvious objective of the heat soak process is to achieve “break now, not later” result. Toughened glass may break without warning due to the expansion of NiS. To avoid the risk of spontaneous glass breakage in fully tempered glass, DFG offered heat soak tests to reduce the potential for spontaneous breakage. It is estimated that up to 95% of nickel sulphide contaminated panes of glass are usually destroyed by this process reducing the chance of on site spontaneous breakage. Our Heat Soaking Conforms to the EN 14179-1 process for monolithic flat thermally toughened safety glass for use in buildings. |