NEWS CENTER

|

Heat treated galssTEMPERED GLASS Tempered glass is a form of glass that has been heat treated in a way to make it stronger and more resistant to damage from impact. It also has the ability to, when broken, break into very small pieces that pose little threat of injury. It was invented in 1874 by Francois Bastie (1830–1901) of Paris, France by quenching almost molten glass in a heated bath of oil. A process he later patented in England. Tempered glass is also called Bastie glass after its creator. It is indistinguishable from annealed or plate glass in appearance.

Popular Uses 1,Automotive UseContractors are appreciative of tempered glass as well because this is a safe and practical option for their projects. The safety that tempered glass can provide for houses is especially highlighted. Its durability can be maximized in a number of ways which is why it is one of the most used construction materials for windows, sliding doors, skylights, bathtub enclosures, shower doors, balcony doors, and even swimming pools. Office environments can even use it for their doors, and they can even use it for their writing boards. Solar panels2,Construction Material 3,Commercial Uses 4,Home Appliances 5,Solar Panels Automotive Use

Most of the vehicles that you see are protected with tempered glass for everyday use. Car windshields use this type of glass since it can lessen the dangers that a normal glass would impose. Once the car has run into a collision, the broken glass shards coming from the windshield can lead to serious complications for the person behind the wheel and his passengers. With the use of tempered glass, the pieces of glass are non-threatening since it is not lethal enough to kill. The use of tempered glass in vehicles has led to increased protection for cars since its strong properties are not likely to break off during an accident and its shards are designed to protect the people from getting injured by it. Construction Material

Contractors are appreciative of tempered glass as well because this is a safe and practical option for their projects. The safety that tempered glass can provide for houses is especially highlighted. Its durability can be maximized in a number of ways which is why it is one of the most used construction materials for windows, sliding doors, skylights, bathtub enclosures, shower doors, balcony doors, and even swimming pools. Office environments can even use it for their doors, and they can even use it for their writing boards. Commercial Uses You can see tempered glass in public spaces and for commercial uses every day. On your daily commute, ads that are on display at bus stops are guarded by tempered glass. There are elevators that are laden with tempered glass as well. The number of commercial uses gives way to the flexibility that tempered glass can give to different applications. Not to mention that it is an affordable choice for different kinds of uses. Home Appliances

Solar panels

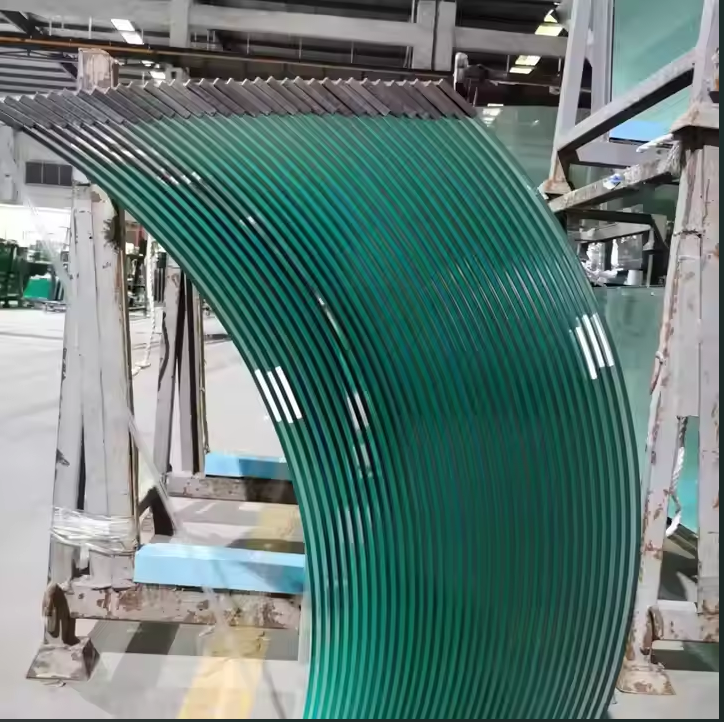

Solar panels are highly regarded as one of the most eco-friendly energy sources for people. With the purpose at which the panels operate, it is no wonder that engineers have constructed their form to withstand heat and extreme stress. With this, tempered glass plays a part in making up the efficient use of the solar panels. Since tempered glass is also known as toughened glass, it is mainly used for panels that require high-strength applications. Additionally, there is an option to choose a plate or a tempered glass for your panels but most manufacturers and consumers usually choose the latter. HEAT SOAKED GLASS Heat Soaked Glass is heated up to 290°C before being bathed at the same temperature to neutralise the nickel and ensure optimum stability. The obvious objective of the heat soak process is to achieve “break now, not later” result. Toughened glass may break without warning due to the expansion of NiS. To avoid the risk of spontaneous glass breakage in fully tempered glass, DFG offered heat soak tests to reduce the potential for spontaneous breakage. It is estimated that up to 95% of nickel sulphide contaminated panes of glass are usually destroyed by this process reducing the chance of on site spontaneous breakage. Our Heat Soaking Conforms to the EN 14179-1 process for monolithic flat thermally toughened safety glass for use in buildings. CURVED GLASS Curved Glass is heating glass to its softing point, form the specific shape conrtolled by the computer,and then cooling process. Curved Glass has same features as flat heat treated glass. With our most advanced curved glass tempering furnace,Lanjing is able to supply special curved glass with multi radius, double curved glass,it’s applied in round skylights,showcases etc.

Below is the specification

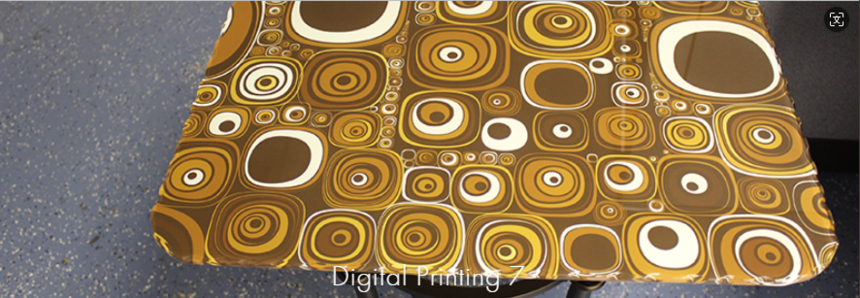

CERAMIC FRITTED GLASS &SILK SCREEN GLASS Ceramic Fritted glass is an inorganic glaze uniformly coated on the surface of glass by a certain glazing method Te suace foms a specia layer of adhesion. The curent glazing processing is mainy screen pinting, roller pinting and digtal glaze printing.After the coating processing, the semi-finished ceramic fritted glass is dried in a drying oven to remove some other thiner. The furnace is heated by the tempering processing. and the glaze are melted finally. after the tempering and cooling processing, the glaze layer and the glass can be permanently combined into one. It has a cetain degree of safety. and at the same time it has a cetain process of alkali resisiance through the melting pocess.Though the use of different of glaze pigments.the finished product is finally produced with rich color, giving customers and designers unlimited imagination.

FEATURES: (1) Decorative China Ceramic Fritted Glass are rich in various patterns. The colors and patterns can be customized according to customer requirements. As an important decorative material, ceramic fritted glass has excellent decoration and stability, is easy to clean, and is not easy to fade. It has strong application value. Thus China ceramic fritted glass manufacturer will design different pattern and colors depending on the customers 'requirements. (2) Stability and Safety The range of use is wide, the color is stable, anti-aging, acid and alkali resistant, non-fading, and decorative effect is outstanding. (3) Various Processed At the same time, it can absorb and reflect part of the solar heat. Different heat treatments are available to obtain glass products with different functions. The ceramic fritted glass can be further processed by lamination, interlayer, hollow, etc., with more functions and effects. Not only the ceramic fritted glass, but also the curved one. SPECIFICATIONS: Thickness 3mm-19mm Max. Size 5800*2500mm STANDARDS: REXI Glass comply with China JC/T1006; Europe EN12150-1; Australia AS/NZS2208 DELIVERY TIME: In Three weeks after order confirmation. APPLICATIONS: More and more China ceramic frit glass suppliers can provide good quality ceramic frit glass that is widely used in building decoration industry; and often as furniture glass, electronic glass, too. 1. Interior and exterior building decoration. 2. Furniture and kitchen appliances 3. Spandrel areas of curtain walls DIGITAL PRINTING GLASS Digital printing glass is to print inorganic glaze (also known as ink) onto the glass surface, and then dry, temper or heat the glaze to be permanently sintered on the glass surface to obtain a wear-resistant, acid and alkali resistant glass. Decorative glass products, highly functional and decorative.

Personalized customization Glass digital printing can achieve highly personalized decorative effects according to customer requirements and designs. whether it's an intricate pattern, photo,or unique image, it can be printed on glass with ease. Hi resolution Digital printing technology has high resolution, allowing for detailed images and crisp details.This allows the pattern printed on the glass to maintain a clear quality and present a beautiful effect. Durability Through special curing and processing, glass digital printing patterns have good durability. these patterns are resistant to fading and peeling and ramain beautiful for long time. Translucency The digital printed pattern on glass retains the light transmittance of the glass allowing light to pass through the pattern, creating a unique lighting effect.

Environmental protection and safety Using environmentally friendly inks and materials, digital printing on glass will not produce harmful substances . this makes it safter to use in interior decoration. Easy and fast The glass digital printing process is simpler and faster than traditional manual or etching processes. it can achieve decorative effects faster, saving time and cost. FIRE PROOF GLASS The fire-proof glass is a single piece of high stress fire-proof glass manufactured by tempering process. When one side of the glass is exposed to fire, it can prevent flame penetration within a certain period of time and maintain good fire resistance integrity.

PRODUCTION CAPABILITY

|

You have probably seen this on the appliances that you have at home and tempered glass is one of the best materials for them because of its heat-resistance and durability. You can most commonly see this use in microwave ovens because they have a tempered glass dish on the device that serves as the asset that can allow food to heat at a high temperature.

You have probably seen this on the appliances that you have at home and tempered glass is one of the best materials for them because of its heat-resistance and durability. You can most commonly see this use in microwave ovens because they have a tempered glass dish on the device that serves as the asset that can allow food to heat at a high temperature.